All posts for

Control valve performer

Tuesday, January 15, 2019

By Prathamesh Badadal

Butterfly valves are a primary selection in case of shut-off application. It is known for its high-performance in fluid flow industry. Actuators are a very crucial part of the complete valve assembly and costs about 30 to 40% of total package cost. The selection of actuator depends on many factors, but most importantly on torque requirement. This blog discusses the hydrodynamic torque behavior of the double offset butterfly valve. Using our Control Valve Performer app, a comparative study is done to understand the hydrodynamic torque and how it behaves in case if flow direction is reversed. Get the insight into butterfly valve hydrodynamic torque for seat and shaft side flow.

Wednesday, May 23, 2018

By Sandip Jadhav

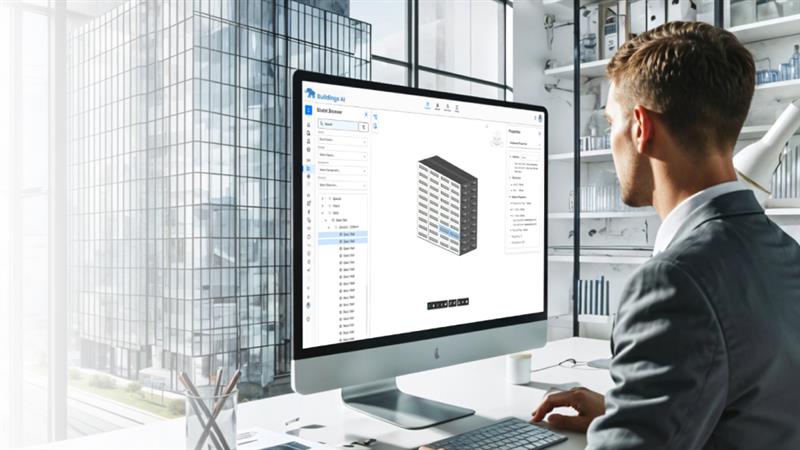

Machine learning (ML) techniques are now widely being used in almost all areas of application. Six months back, CCTech Research started investigating how we may use ML in the area of Design of Mechanical Systems. One of the key application we were particularly interested is in Control Valve industry. simulationHub's Control Valve Performer app is already calculating valve performance within minutes compared to weeks in traditional CFD way. But one still yearns for a solution that could predict the flow performance in less than 5 seconds. The machine learning app developed by CCTech research team is now able to predict the value performance within seconds. Read more about the app, what went into creating the app and the app workflow.

Monday, April 16, 2018

By Chaitanya Rane

Designing of control valves involves a lot of design parameters which needs to be considered to ensure safety and durability of the valve. One such prominent parameter is the Coefficient of Hydrodynamic Torque (Cdt). Control Valve Performer app by simulationHub now calculates and delivers the Cdt curve for all rotary motion valves. Here I am explaining all about this new feature and help make your valve design more efficient.

Saturday, October 21, 2017

By Praveen Kumar

The heart of the control valve is the trim, especially the mating parts that throttle the stream to the demands of the controller. Each process is unique in nature and demands unique flow control characteristics. The synergy between what is demanded and what is supplied by the valve can be achieved by re-shaping the valve trim to get desired valve characteristics. Here I am sharing my experience of using simulationHub Control Valve Performer app with underlying CFD technology as a tool to evaluate the valve trim design of a lift valve.

Recent posts