Written by Praveen Kumar

Saturday, October 21, 2017

Valve trim design using Autonomous Valve CFD

By

Praveen Kumar

The heart of the control valve is the trim, especially the mating parts that throttle the stream to the demands of the controller. Each process is unique in nature and demands unique flow control characteristics. The synergy between what is demanded and what is supplied by the valve can be achieved by re-shaping the valve trim to get desired valve characteristics. In this blog, I am sharing my experience of using simulationHub Autonomous Valve CFD app with underlying CFD technology as a tool to evaluate the valve trim design of a lift valve.

Valve trim and valve characteristics

The operating parts of a valve which are normally exposed to the process fluid are referred to as 'valve trim'. Usually parts like stem, plug, disc, seating surface etc. are called as valve trim. Valve trim is the physical shape of the plug and seat arrangement. The shape of the valve plug determines the flow characteristics of the valve.

Different valve characterizations may be achieved by re-shaping the valve trim. For instance, the plug profiles of a stem-guided globe valve may be modified to achieve the common quick-opening, linear, and equal-percentage characteristics.

Valve trim shape and characteristics

The relationship between valve stem position and the flow rate through a control valve is described by a curve called the valve's flow characteristic curve, or simply the valve characteristic. The inherent characteristic curve is a plot of the percent of valve opening vs. the percent of maximum flow coefficient (CV). This is determined by measuring the flow rate at various positions of valve travel with a fixed differential pressure across the valve. The CV value is calculated at each valve position using a form of the generalized Control Valve CV equation.

Quick Open : A quick opening valve plug produces a large increase in flow for a small initial change in stem travel. Near maximum flow is reached at a relatively low percentage of maximum stem lift. Quick open plugs are used for on-off applications designed to produce maximum flow quickly.

Linear : An inherently linear characteristic produces equal changes in flow per unit of valve stroke regardless of plug position. Linear plugs are used on those systems where the valve pressure drop is a major portion of the total system pressure drop.

Equal Percentage : The equal percentage valve plug produces the same percentage change in flow per fixed increment of valve stroke at any location on its characteristic curve. The equal percentage is the characteristic most commonly used in process control.

Importance of valve trim design

To understand the importance of valve trim design, let us get familiar with the installed valve characteristics and how it is different than the inherent valve characteristics.

When a constant pressure drop is maintained across the valve, the characteristic of the valve alone controls the flow, which is referred to as the inherent flow characteristic. But, when the valve is installed with pumps, piping and fittings, heat exchanger, and other process equipment, the flow is controlled by the installed characteristics that include both the valve and the pipeline effects.

The installed characteristic curve will be different than the inherent characteristic curve because the differential pressure across the valve will change with a change in valve position. How the curve shifts, is determined by the shape of the pump curve and the amount of static head in the system.

Installed valve characteristics

For example, when a valve with equal percentage characteristics is installed in a system, the shift in the inherent curve results in the control valve with an installed characteristic that is closer to linear. A control valve with linear trim will exhibit consistent responsiveness only with a constant pressure drop, while equal percentage trim is designed to counteract the droop caused by changing pressure drop when installed in a process system.

Hence, control valve trim is designed and manufactured in a variety of different characteristics to provide the desired installed behavior.

Case study – Evaluating valve trim design of a lift valve

Now it's time to apply our knowledge and see the impact of valve design on the valve characteristics. For this study, we have considered a lift valve of DN28 size. In this case, the valve trim is the valve plug.

Lift valve

The idea is to evaluate the valve characteristic of the actual plug design and try to modify the valve plug design to see the change in characteristics curve. Autodesk Fusion360 is used for modifying the design and simulationHub Autonomous Valve CFD app is used to extract CV curve through series of CFD simulations at different valve openings. The two new plug profiles in comparison with the actual plug profile are shown here.

Lift valve plug profile

To plot the CV curve, the valve is simulated for 8 valve openings for all three plug profiles. So, a total of 24 individual CFD simulations are carried out. For each simulation, complete CFD workflow should be performed. This includes fluid volume extraction, cleanup, meshing, solver inputs, post-processing, and plotting the CV curve.

No worries, the CFD workflow is completely automated in the Autonomous Valve CFD app. Just upload the CAD model, provide few valve opening settings and you are good to go. All the inputs related to CFD including flow conditions, meshing and solver details all are automatically computed by the algorithm. As the simulations are carried out in the cloud, the CFD results and CV curve is available for review, real fast. Thanks to the Autonomous Valve CFD application!! The complete design study was completed in "less than an hour".

Flow characteristics of actual profile

The CV curve and the values obtained from the app for all three plug designs are used to generate the flow characteristic curve. As expected, changes in the valve plug design show modified valve characteristics.

Impact of valve trim design on valve characteristics

It is clear from the flow characteristic curves that the actual valve has a quick opening nature. And, by modifying the plug profile the inherent characteristic of the valve has changed. The plug with profile-01 shifted the curve from quick opening to a valve characteristic closer to linear. The plug with profile-02 shifted the curve from quick opening to a valve characteristic inclined towards equal percentage.

Many valve types, such as butterfly, eccentric disk, and ball valves, have an inherent characteristic which cannot be changed except with characterizable positioner cams. A similar design study for the same can be conducted using Autonomous Valve CFD app.

Unleash the designer within

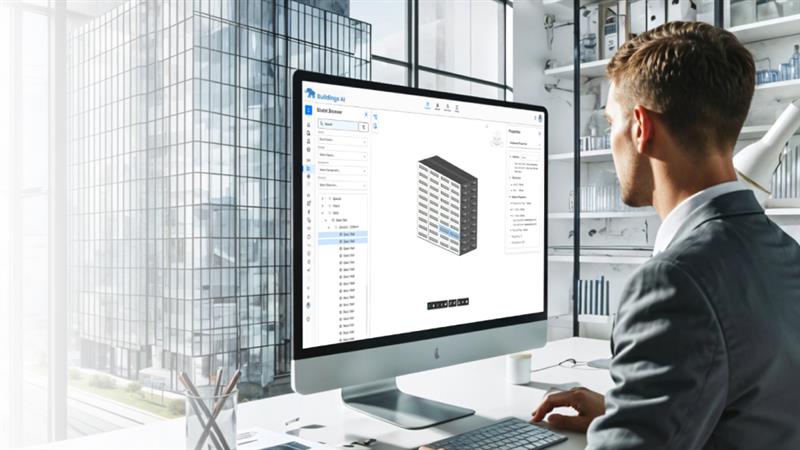

Gone are the days when control valve design simulations were performed by experienced CFD engineers. What if we bypass the old way of designers providing design concepts to the simulation experts and then wait for the simulation results, to reiterate and improve the design. Welcome to the new era of CFD democratization. Autonomous Valve CFD(AVC) app enables design engineers to directly simulate their valve design without any requirement of CFD expertise.

The AVC app is crafted for design engineers by completely taking out the CFD related inputs from the user interface. After uploading the CAD model, the user intuitive UI guides the user to provide simple inputs like valve type, rotating/moving bodies, minimum and maximum valve opening angle/position, inlet and outlet pipe connections for the proposed design. The application determines the CV values for the specified range of trim positions using a series of CFD simulations in the cloud facility. The results can be viewed through the browser from any internet connected device. At the end of the simulation, the user can download a ready-to-use CFD result report, auto-generated by the app. The design team can then quickly develop multiple improved valve designs and evaluate their performance, to find the optimal solution in a much shorter time frame.

Personally, as a CFD engineer, AVC app let me use CFD as just a tool and complete the design work. Usually, one gets carried away by the mammoth amount of work (fluid volume extraction, cleanup, meshing, solver, convergence, post, report) involved in carrying out the CFD simulation and loose the focus on the design aspect of the valve. AVC app made it easier and more realistic to focus on the designing part.

Comments

Recent posts