Written by Praveen Kumar

Monday, June 16, 2025

The Gate Valve that stood between Chernobyl and an even Greater Disaster

By

Praveen Kumar

It all started with a scene from the HBO miniseries Chernobyl...

I was watching Chernobyl over the weekend—yes, the gripping HBO miniseries that dramatizes one of the worst nuclear disasters in history. If you haven’t seen it yet, I highly recommend it. The storytelling, tension, and historical depth are all there.

But this particular scene really stuck with me.

A scene from Episode 3 of the HBO miniseries Chernobyl - Opening the Gate Valve

A Desperate Mission in the Dark

April 26, 1986. The Chernobyl Nuclear Power Plant in Soviet Ukraine had already suffered the worst nuclear disaster in history. Reactor 4 had exploded, spewing radioactive debris into the air. But the crisis was far from over.

Reactor 4 after the disaster [source: IAEA Imagebank]

Beneath the reactor, a massive pool of cooling water had accumulated in the basement. The molten nuclear fuel was melting downward, threatening to come into contact with the water. If this happened, it could trigger a catastrophic steam explosion—one that could have destroyed the remaining reactors and released even more radioactive material across Europe.

To prevent this, three engineers - Alexei Ananenko, Valeri Bezpalov, and Boris Baranov volunteered for a near-suicidal mission. Their task? Locate and manually open a gate valve to drain the trapped water. They had to do this in near-total darkness, wading through radiation-contaminated water, knowing that exposure could be fatal.

This is the story of how a single gate valve played a pivotal role in preventing an even greater catastrophe.

The Role of the Gate Valve in the Crisis

The gate valve in question was a simple yet essential piece of equipment. Gate valves are designed to either completely stop or allow the flow of fluid by raising or lowering a gate inside the valve body. In the case of Chernobyl, this gate valve was part of the emergency cooling system. It had to be manually opened to allow the trapped water to drain out, preventing it from becoming the fuel for a secondary explosion. Had it failed to open, the water would have remained trapped, setting the stage for an explosion that could have made Chernobyl’s initial disaster look small in comparison.

Despite the extreme conditions—total darkness, rising radiation levels, and the ever-present risk of exposure—the three engineers managed to locate the valve and open it, allowing the water to drain safely. Their heroic actions likely prevented millions of deaths and an even more devastating nuclear disaster.

Valves in High-Stakes Environments

Chernobyl is a dramatic example, but valves play a crucial role in many other high-risk industries:

- Nuclear Power Plants : Multiple valve types regulate coolant flow, reactor pressure, and emergency shutdown mechanisms. Failure of any critical valve can lead to catastrophic overheating or radiation leaks.

- Oil & Gas Industry: Blowout preventers (BOPs) and emergency shut-off valves stop uncontrolled pressure surges, such as in the Deepwater Horizon disaster

- Chemical Plants: Valves control the flow of hazardous chemicals, preventing leaks and explosions.

- Dams & Water ManagementDams & Water Management: Large gate valves regulate water flow, helping prevent dam failures and flooding.

While the Chernobyl story highlights a single gate valve in a desperate situation, the reality is that valve reliability is a make-or-break factor in almost every critical infrastructure system.

Lessons from Chernobyl: What If the Valve Had Failed?

The gate valve worked when it mattered most—but what if it hadn't?

- What if the valve was wrongly sized or the flow capacity Cv, was inaccurate? If the Cv value was off, the valve might not have been able to drain the water quickly enough, leaving the reactor vulnerable to a steam explosion.

- What if the valve had been misdesigned? If it wasn’t built to withstand the pressure, it could have jammed or broken.

These are not hypothetical concerns. Valve failures have caused real disasters, including:

- The Deepwater Horizon spill (2010): A blowout preventer failed, leading to a massive oil spill.

- The Bhopal Gas Tragedy (1984): Malfunctioning safety valves allowed toxic gas to escape, killing thousands.

- The San Bruno Pipeline Explosion (2010): Slow response in shutting off a gas valve worsened the explosion’s impact.

Valves must function perfectly in high-stakes scenarios. There’s no second chance when safety is on the line.

Role of Simulation in Ensuring Valve Reliability

In industries where failure is not an option, ensuring the reliability of valves is absolutely critical. Traditionally, valve manufacturers have relied on physical testing to validate performance, conducting real-world tests in controlled environments to ensure that valves meet safety, pressure, and flow requirements. However, this process is not only time-consuming but also costly and often impractical, especially for large or complex valve designs.

Modern engineering has embraced advanced simulations - an invaluable alternative, allowing engineers to test valve performance in a virtual environment before any physical prototype is even created. The key advantages of simulation over traditional physical testing include:

- Cost reduction: Physical testing often requires significant resources. Simulation eliminates the need for multiple physical prototypes.

- Time Efficiency: Physical testing can take weeks or even months. With simulation, engineers can get results within minutes, allowing them to iterate and refine designs in real-time.

- Design Optimization: Engineers can test multiple valve designs and operating scenarios virtually, ensuring better performance from the start.

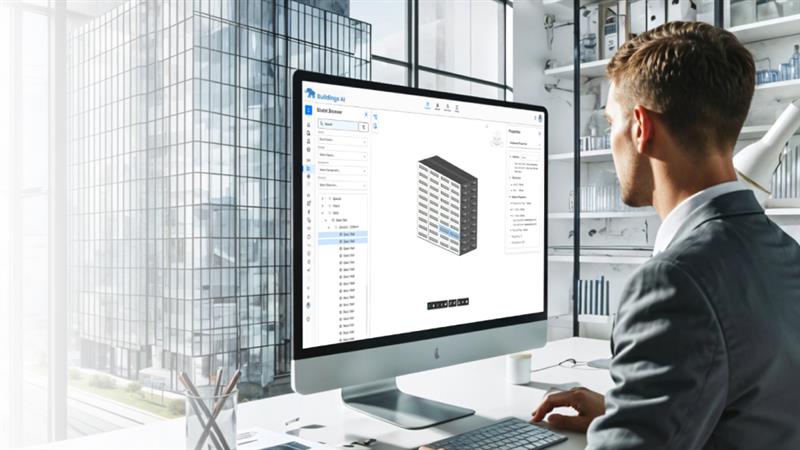

Autonomous Valve CFD: Revolutionizing Valve Testing

Autonomous Valve CFD (AVC) takes the power of simulation one step further, democratizing valve testing and design optimization. Traditionally, CFD (Computational Fluid Dynamics) simulations required significant expertise in fluid dynamics and access to expensive software and hardware. However, AVC simplifies this process by providing an easy-to-use, cloud-based platform that doesn’t require any specialized CFD knowledge.

Autonomous Valve CFD

What once took weeks of testing/simulation can now be accomplished in hours with AVC’s cloud-powered computing infrastructure. Engineers can run multiple design scenarios quickly and receive ready-to-use performance reports within an hour, cutting down design time drastically.

Know more

Request Demo

Comments

Recent posts