Written by Aaditya Ruiker

Wednesday, March 25, 2020

Performance Evaluation of Ball Valve for different V-port Angles

By

Aaditya Ruiker

The V-ball or V-port ball valve is similar to a conventional ball valve where a V-notch is

provided on a ball-shaped disk to control flow using a rotational quarter-turn motion.

V "port" is an exclusive design that provides precise flow with the ability to modulate

and control the flow with 15°, 30°, 45°, 60° or 90° degree V "notches".

These control valves are used extensively in chemical applications, including the most

challenging services for numerous advantages.

Advantages of a V- port ball valve:

Flow control

The precision of V-Ball valves offers equal percentage flow characteristics that are

generally not associated with a standard ball valve.

Bubble tight shut-off

V-ball valves have the capability of tight shut-off. Thus, additional shut-off valves are

not required when using a V-ball valve over globe control valves.

Lower pressure drop

V-Ball valves also have higher flow coefficients (Cv) compared to the same size globe

valve which diverts flow and uses a plug to control the flow through the valve. This

means that smaller V-Ball sizes can be used to achieve the same flow rate as a larger

size globe valve.

Higher shut-sff pressure

The 90° ball rotation allows the V-Ball to shut off at higher working pressures. Thus,

allowing lower torque actuators to be used, resulting in cost-saving and higher

efficiency for the end-user.

Role of Autonomous Valve CFD in design analysis

As the v-port ball valves are used for the precise control over the flow, it is necessary

to analyze them and be sure about their performance in terms of pressure drop and the

flow-rate. CFD simulations are beneficial for valve designers in the early stages of

design processes without manufacturing actual prototypes. But due to very high

computer hardware costs and sophisticated numerical methodologies, CFD may not be

the practical solution for them.

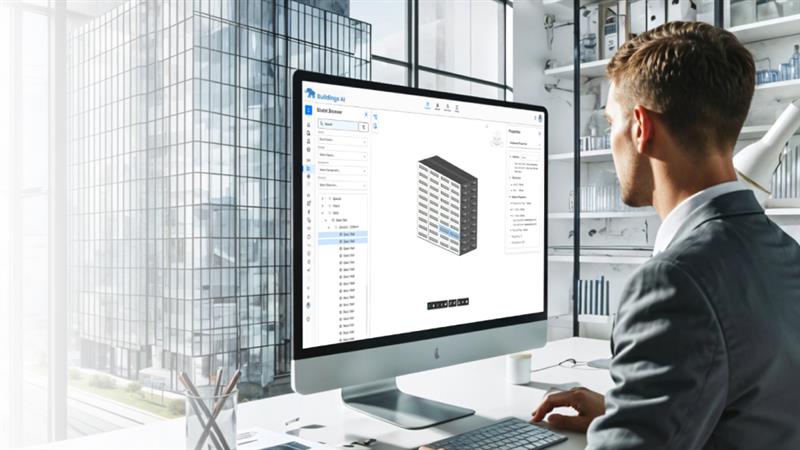

Autonomous Valve CFD app is designed in such a way that helps valve designers to

focus on valve design and leave the task of performing the CFD simulation as per the

flow-loop testing methodologies to the app. Using simulationHub valve designers able

to :

Run a valve simulation for all the opening angles with just one click

Focus on designing the valve geometry rather than sophisticated CFD methodology.

Analyze and update design quickly to reduce the entire design cycle time.

Access their design from multiple locations and share them among the team members.

Here, I am presenting the design of experiments (DOE) performed for the different

configurations of ball V "notches" and the predicted flow performance characteristics

over the full range of opening starting from zero to 90°.

Geometry and flow loop testing setup

The 10-inch ball valve with different V-port configurations ϕ[15°, 30°,45°,60°, and

90°] are simulated using the Autonomous Valve CFD app. The flow direction in such a

way that V-port is downstream of the valve and ball rotated from V-port to the arc.

User-defined inputs:

Standard schedule-40 pipe diameter pipe connections were attached to the valve body.

The pipe lengths used in the simulation are 2.5D upstream and 10D downstream of the valve, where D is the nominal pipe size diameter.

The roughness of the pipe and valve body is considered to be 45.72 microns with a smooth ball surface.

Standardization of virtual flow-loop testing in CFD methodology

Autonomous Valve CFD follows ANSI/ISA standards and experimental flow conditions in CFD methodology to replicate flow loop testing virtually.

All CFD processes CAD-cleanup, fluid volume extraction, meshing were run in the simulationHub cloud-platform automatically. The following are the details of the

number of simulations completed for the design of iterations.

Once the simulations are completed we are ready to analyze the results obtained.

Analyzing results

In general, the flow performance of the valve is evaluated using flow coefficient (Cv), which is the function of flow-rate and pressure drop. The effect of V-ports on the flow

coefficient, Cv, can be found in following figure.

Following are the observations:

It shows that Cv increases with an increase in valve opening and V-port angle(ϕ).

V-port seems to be the most appropriate one for the equal percentage flow performance control over the round port ball valve.

It can also be observed that for low angle V-port valves provide better control for the

low flow-rate applications.

Although the narrow V-port can control the volume flow rate linearly or equal

percentage , it also can induce cavitation in the flow even though the ball valve is fully

open. Figure 5 has observed sharp velocity contours in comparison flow-contours of

V30 and V90 ball valves. This increases the very high localized pressure and chances to

induce a cavitation prone zone.

Observations :

The V-port ball provides an inherent equal percentage flow characteristic.

It is observed that cavitation indices increase as the angle of V-port decreases.

simulationHub valve CFD made the valve designer’s job easy to carry out a number of design iterations.

Comments

Recent posts